THE INNOVATIVE TECHNOLOGY FOR ARTIFICIAL GRASS

Artificial grass is the last wonder application of the plastic textile sector having worldwide demand with double digit growing trend.

Polypropylene, polyethylene, PA and PET are the basic raw materials mainly used for producing yarn for sports, leisure and landscaping applications.

The artificial grass industry is a deep B2B market with a supply chain involving a broad range of process: polymer supplier, yarn producer, handling, tufting, up to field installation and maintenance. Ali these processes are strategie to realize a first quality product and service.

In the artificial grass sector, SIMA together with Dietze-Schell put in piace their wide experience on extrusion and handling process to develop complete turn key solution producing wrapped and texturized yarn bobbins ready to be tufted. The production of artificial turf can be done inline from extruder line or offline from an unwinding device. The texturized filaments can additionally be entangled with support yarn in a joined wrapping spindle and subsequently wound to bobbins with a precision cross winder.

The individuai winding positions can be assembled to networked production lines. The compact design permits operation even in a confined space. Fibrillateci tape, various shape monofilament mono and bicomponent, bicolor or 3-colour, having technical features to comply with sport associations standard (FIFNUEFA) or simply according to specific customer requirements, can be produced on SIMA + Dietze-Schell synthetic grass equipments.

SIMA ARTIFICIAL GRASS PRODUCTION PROCESS MEANS:

DIETZE-SCHELL AUTOMATIC TEXTURIZING AND WINDING TECHNOLOGY FOR COMPLETE TURN KEY SOLUTION

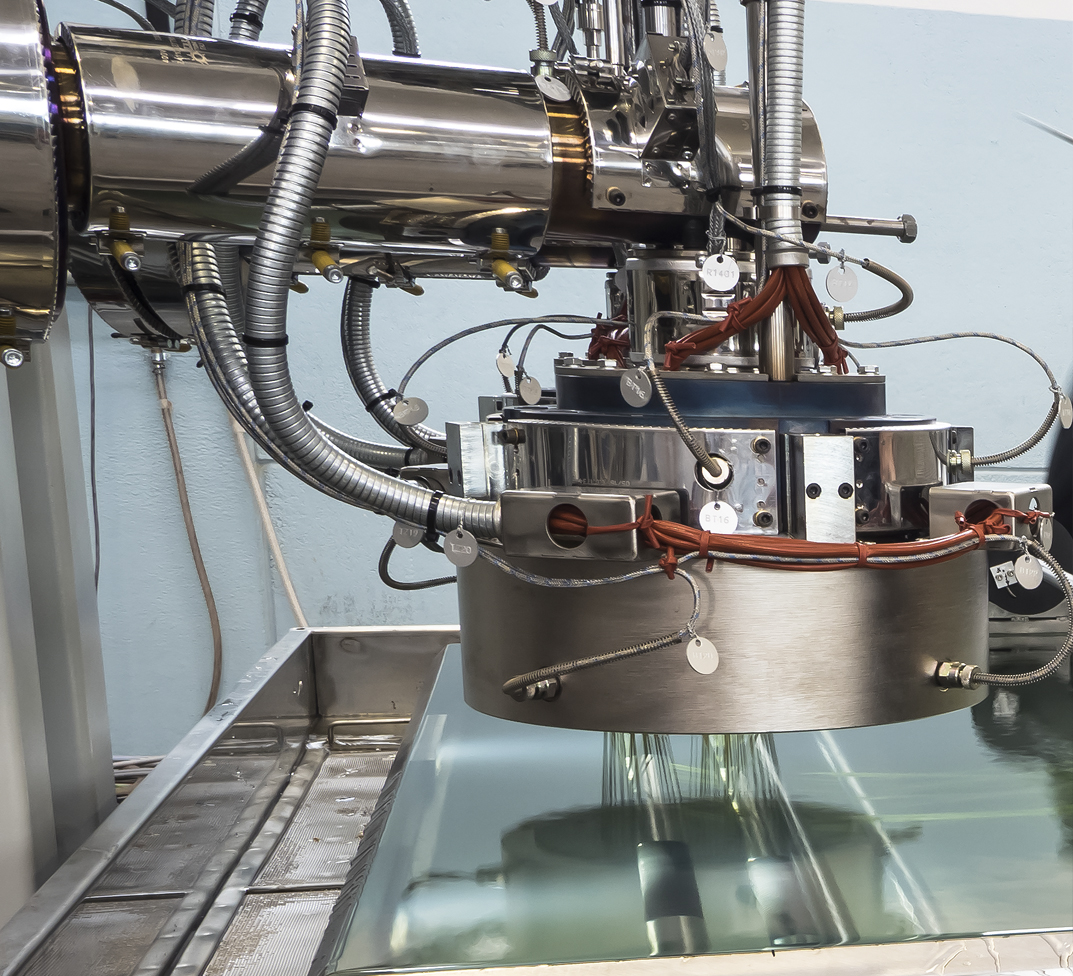

The DS 200 G is the air texturizing machine suitable for a wide range of technical yarn including plastic filament for artificial turf application. The unit can handle bundles of monofilament and fibrillateci tape of LLDPE, PP, PA, in a yarn count up to 20.000dtex. The machine is designed far permanent operation in line with extrusion or offline from an unwinding device. The texturized filaments can also be entangled with a support yarn winding the whole bundle in perfect nature look in the down-stream precision cross winder like DS 350. The DS 352, fully automatic precision cross winder is the best solution to take up textile grass filament or bundle in a yarn count range up to 25.000dtex. The winding positions are in individuai compact frames with one or two winding positions each. Empty tube are fed from machine frame back. Full bobbins are ejected on a belt or a tray in the machine frame back as well. The fully automatic bobbin swap at full production speed. DS 352 is the low labor cost technology for all artificial grass filament producers.

DOWNLOAD DOCUMENTS

[wppcp_guest_content message=”” ]

You must be register in order to access our documents file. Please select one of the two action below:

[/wppcp_guest_content]